เครื่องทดสอบอเนกประสงค์ Universal Testing Machine

จำหน่าย เครื่องทดสอบอเนกประสงค์หรือ UTM เป็นเครื่องทดสอบคู่ที่สามารถทำการทดสอบแรงอัดและแรงดึงได้

The Universal Testing Machine or the UTM is dual-testing machine can perform compression and tensile testing.

The Universal testing machine enables measurement of firmness and harness. It is based on a physical property called the indentation force deflection (IFD). Which is calculated by determining the force required to deflect a test piece. Which is a percentage of its original thickness using a circular indentor. This applies a force, while also recording the degree of indentation.

As the name suggests, it is called "Universal testing Machine" because it can test tensile and compression of various materials. For example, textiles, rubber, springs, plastic and others. The tests conform with relevant testing standards such as ASTM, ISO, JIS, GB, and many others.

Compression and Tensile Testing

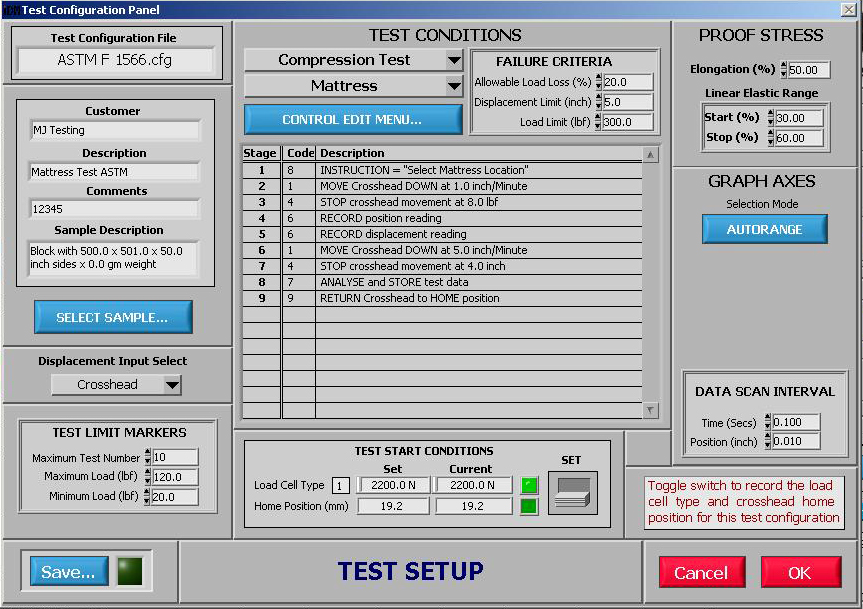

IDM Instruments' UTM comes with fixed dual testing capabilities. Which comprises of compression testing on the inner frame. As well as tensile strength testing on the outer frame. This incorporation of dual testing space design is beneficial. as it eliminates the need of having two machines required for testing. The same machine is useful for both tests. The twin column bench-mounted UTM has a strong and durable frame. Thus, can withstand many years of use. It offers excellent accuracy and ease of use. It operates on the IDM Instruments Pty Ltd software program.

Why is tensile testing important?

Tensile testing is a common method used to test quality of materials. The tensile of a sample is determined by the force required to elongate (applying tension) until it reaches breakage point. For example, a rope is pulled from both ends until it reaches the breaking point. This test helps quality experst determine whether the material/ product would sustain different circumsances it goes through. The minimum tensile strength is determined by the testing standard referred. The applications of tensile testing are limitless. From textile companies to research orgnisations to aerospace companies, tensile tetsing is performed by every quality testing department.

We have so mnay clinets who have used our universal testing machine to test tensile of foam, ropes, wires, plastic, textiles, etc.

What is the importance of the compression test?

Why choose IDM's Universal testing Machine for tensile and compression testing?

Custom Universal Testing Machine

We also manufacture custom UTM to accommodate as per customer needs. For example, a wider testing space removes the sample length restrictions. This includes cutom load cell capacities that can be expanded or reduced in tonnage based on the test and material being tested.