เครื่องรีดและเครื่องทดสอบความทนทานของที่นอน Mattress Rollator & Durability Tester

จำหน่าย เครื่องรีดและเครื่องทดสอบความทนทานของที่นอน Mattress Rollator & Durability Tester ทดสอบเกี่ยวกับน้ำหนักที่กลิ้งไปมาบนที่นอน ลูกกลิ้งเคลื่อนที่จากด้านหนึ่งไปอีกด้านหนึ่งบนที่นอนเพื่อจำลองการนอนหลับ

Mattress Rollator & Durability Tester determines the durability of all types of mattress. Including Boxspring, Innerspring, Latex or Polyurethane mattress. It does this by simulating long-term use conditions. The testing procedure involves a specific weight load rolling over the mattress. The roller traverses from side to side across the mattress simulating a realistic sleeping action.It then identifies changes in its dimensions. For example, thickness and firmness. Thus, it helps in quality testing of mattress, especially, on the durability dimension. This latest model does not require large moving cross beam. Therefore, providing a safer, smaller work area with less moving hazards. Moreover, the operational height is low. Thus, minimizing lifting of mattresses and making it easier for loading and unloading. Adjustable travel limits are fitted to allow for easy setup for different mattress sizes.

Also available is the option of having the Mattress Compression Testing feature, saving on space. And the need to remove the samples as they can be tested for firmness in the same machine. With the added fixture, more tests are possible. For example, all Foam ILD & IFD and spring compression tests. That too meeting necessary international standards. We are a leading supplier within the mattress testing industry. This includes Mattress Rollator & Durability Tester. As we are trusted by big brands all around the world. For instance, A.H. Beard, Original Mattress Co., Sealy and Tempur.

The Mattress Rollator consists of a weighted roller which moves width ways across a test mattress to simulate body movement. The length of stroke to which the Roller moves is very easily adjusted, by sliding the stroke adjustors left or right, to suit the relevant mattress under test. Unloading and loading of the Roller onto the test mattress is done easily via a motor driven lifting assembly.

A Light Curtain Safety Enclosure is used with the Mattress Rollator to ensure no harm comes to the operator or others in the testing area. The Light Curtain Safety Enclosure together with the Mirror Reflectors ensures optimum safety in that as soon as foreign objects obstruct the Light Curtain, the Mattress Rollator will stop operating.

A Carrier Frame has been constructed to suit all sized mattresses, and should be placed in such a way that the Roller rolls from side to side and in the centre of the mattress. This Roller movement should then simulate a realistic sleeper action. Adjustable end stops are fitted across the side of the mattress to hold the mattress during testing.

Control Panel

Optional Models

| IDM-M0015-M1 | Mattress Rollator & Durability Tester with Safety Light Curtain |

| IDM-M0015-M2 | Mattress Rollator & Durability Tester (without Safety Light Curtain) |

| IDM-M0015-M3 | Mattress Rollator & Durability Tester with safety Light Curtain & Compression Testing Feature |

Optional Items

1. Round Roller - BS EN 1957 - IDM-M0015-OP1

The Round Roller is also made of coated plywood sections, with a diameter of 250mm ± 1mm at the ends and 300mm ± 1mm in the middle. It is capable of following the surface of the mattress, and is free to move up and down to follow the mattress surface. The Round Roller is made of coated plywood sections, with a diameter of 250mm ± 1mm at the ends and 300mm ± 1mm in the middle. The total length of the Round Roller is 1000mm ± 2mm, applying a load of 1400N ± 7N. It is capable of following the surface of the mattress, and is free to move up and down to follow the mattress surface.

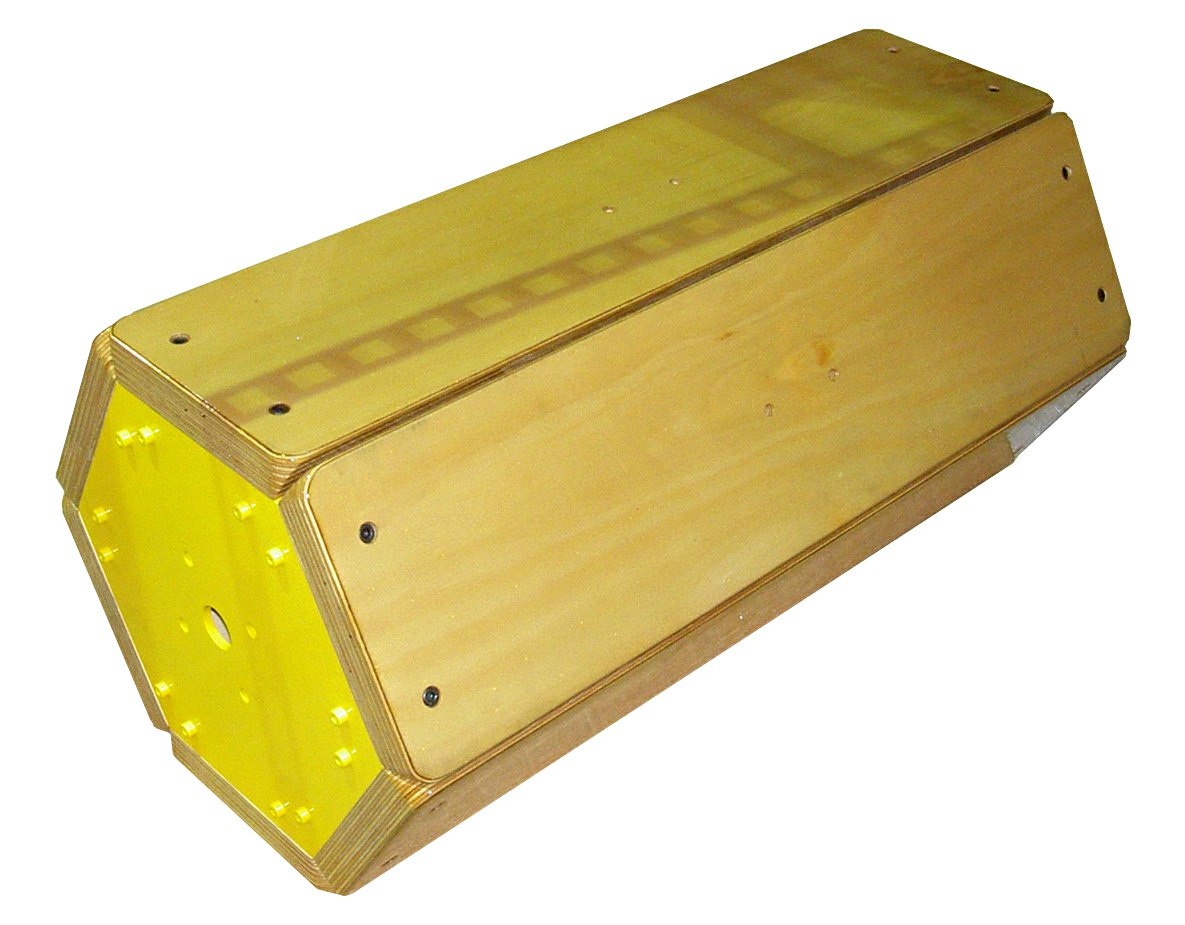

2. 6 Sided Hexagonal Roller – ASTM F1566 - IDM-M0015-OP2

The 6-Sided Roller is made from coated plywood sections, and each section has the option of additional cleats. The cleats are attached via a nut and bolt so the internal section of the Roller will need to be accessed. The Roller is a six sided construction made from coated plywood sections. Each section has the option of additional cleats to be added. The cleats are attached via a nut and bolt so the internal section of the Roller will need to be accessed. Its’ total length is 36 inches ± 3 inches (915.0 ± 76mm) with a weight of 240 pounds ±10 pounds (109.0kg ± 4kg). The weight of the Roller can be adjusted if required via removal of one of the six sections to access the shaft. The shaft can then be made heavier or lighter by adding or removing weights. The Roller is mounted in such a way that at no time during the test procedure is it affected by a vertical force.

3. 8 Sided Roller

4. Cleats

5. Compression Testing Feature

6. Light Curtain

Durability Test Apparatus – The Mattress Rollator

The Mattress Rollator is used to determine the durability of any type of mattress and boxspring unit, regardless of the materials of construction, by simulating long-term use conditions.

The Mattress Rollator consists of a weighted roller which moves width ways across a test mattress to simulate body movement. The length of stroke to which the Roller moves is adjusted, to suit the relevant standard under test. A frame supports the mattress and base under test while a safety light curtain around the whole Mattress Rollator stops any accidental placement of foreign objects such as hands in harmful positions.

Applications

- Boxspring Mattresses

- Innerspring Mattresses

- Polyurethane Mattresses

Features

- Electronic Counter and Totalizer

- Solid Construction

- Light Curtain Safety Enclosure

- Simple Stroke Setting

- Electrical: 320-440VAC @ 50/60 HZ 3 Phase or 100-250 VAC @ 50/60 HZ 3 Phase

- Dimensions: 2,100mm x 4,000mm x 2,150mm

- Weight: 600kg

Benefits

- Lower price - better value

- Reduced weight & dimensions - Lower shipping costs

- Quick and easy installation process

- Option of additional Mattress Compression testing feature

Standards

- ASTM F1566 - Standard Test Methods for Evaluation of Innersprings, Boxsprings, Mattresses or Mattress Sets

- American Innerspring Manufacturers

- ASTM D3574 - Test B - Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams

- ISO 3386:1984 - Polymeric materials, cellular flexible — Determination of stress-strain characteristic in compression — Part 2: High density materials

- ISO 2439 - Flexible cellular polymeric materials — Determination of hardness (indentation technique)

- BS EN 1957:2000 - Domestic furniture. Beds and mattresses. Test methods for the determination of functional characteristics

- GB 10807 - Flexible cellular polymeric materials -- Determination of hardness (indentation technique)

- JIS K 6400 - Flexible cellular polymeric materials - Physical properties - Part 2: Determination of hardness (indentation technique) and stress-strain characteristics in compression

- AS 2281 - Flexible cellular polyurethane for seat cushioning and bedding

- AS 2282.8 - Methods of testing flexible cellular polyurethane Determination of force deflection